Im going to help a couple buddies install a wide bow window in an old opening. They have more experience, but Im wondering about part of their plan and would like some advice on that.

The wall beneath the opening is 4 thick concrete block, with brick facing. Theres currently a 2 concrete slab sill under the existing window, extending from inner edge of wall to beyond the brick. Plan is to leave that, which sounds fine to me, since most big window replacements in that neighborhood have done that. But the slab is set at a pretty steep pitch, and the window base is flat, and the question is how to deal with that wedge-shaped gap when giving the window solid support over the wall. (They say were going to be adding braces and insulation underneath, but Ill be ignoring that here, for simplicity.)

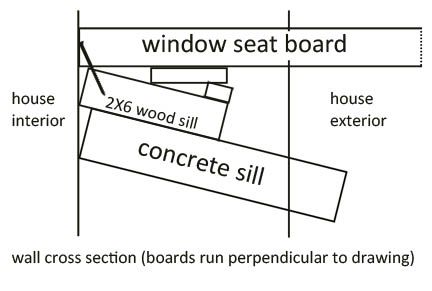

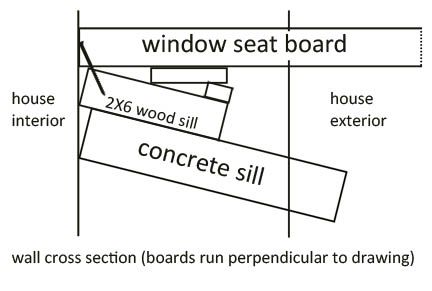

Their plan is, I hope, clear in the diagram:

Three boards will be added under the window seat, running across the window bottom: A 2X6 sill plate, laid flat on the concrete slab, so it has the same steep pitch as the slab. A thinner, narrower board on top of that, to provide a flat surface for some of the seat near the outer part of the wall. And a narrower board between the wood sill and that added board, to force the board level. Shimming as needed. The plan is to use no bottom fasteners at all to secure the seatboard, aside from some wood screws driven at an angle through the seatboard edge and into the 2X. That way the seat board finish wont be marred at all, and the screws will be covered by the casing.

Before I heard that, I had assumed we were going to cut thick wedges to fill the gap between concrete and wood sills, and space them periodically perpendicular to the wall. That way the whole 2X6 would be flat and resting on flat-topped wedges (or nearly so, there would still be thin shims needed no doubt), which sounds a lot firmer to me. The way they plan to do it, the seat doesnt have any true flat base anywhere over the wall, because when you look at the diagram its basically boards resting on board corners only. Are just board corners strong enough? (And straight enough? Little strips of board edge corner that have pulled off would change the straightness quite a bit, Id think.) And it seems like itd be easier to fit in some insulation using wedges instead of boards. Id also like to see more seatboard fasteners than just the diagonal wood screws, some nails near the outer edge of the wall.

What would you do?

The wall beneath the opening is 4 thick concrete block, with brick facing. Theres currently a 2 concrete slab sill under the existing window, extending from inner edge of wall to beyond the brick. Plan is to leave that, which sounds fine to me, since most big window replacements in that neighborhood have done that. But the slab is set at a pretty steep pitch, and the window base is flat, and the question is how to deal with that wedge-shaped gap when giving the window solid support over the wall. (They say were going to be adding braces and insulation underneath, but Ill be ignoring that here, for simplicity.)

Their plan is, I hope, clear in the diagram:

Three boards will be added under the window seat, running across the window bottom: A 2X6 sill plate, laid flat on the concrete slab, so it has the same steep pitch as the slab. A thinner, narrower board on top of that, to provide a flat surface for some of the seat near the outer part of the wall. And a narrower board between the wood sill and that added board, to force the board level. Shimming as needed. The plan is to use no bottom fasteners at all to secure the seatboard, aside from some wood screws driven at an angle through the seatboard edge and into the 2X. That way the seat board finish wont be marred at all, and the screws will be covered by the casing.

Before I heard that, I had assumed we were going to cut thick wedges to fill the gap between concrete and wood sills, and space them periodically perpendicular to the wall. That way the whole 2X6 would be flat and resting on flat-topped wedges (or nearly so, there would still be thin shims needed no doubt), which sounds a lot firmer to me. The way they plan to do it, the seat doesnt have any true flat base anywhere over the wall, because when you look at the diagram its basically boards resting on board corners only. Are just board corners strong enough? (And straight enough? Little strips of board edge corner that have pulled off would change the straightness quite a bit, Id think.) And it seems like itd be easier to fit in some insulation using wedges instead of boards. Id also like to see more seatboard fasteners than just the diagonal wood screws, some nails near the outer edge of the wall.

What would you do?