You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

can i put water based poly over oil base?

- Thread starter mayhem69

- Start date

Help Support House Repair Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Nestor_Kelebay

Emperor Penguin

- Joined

- Mar 28, 2009

- Messages

- 1,844

- Reaction score

- 5

Mayhem69:

I'm neither a hardwood flooring contractor nor a coatings chemist, but that gameplan raises a lot of questions in my mind. Right off the bat I don't see the logic in putting harder coatings over softer ones. That's a no-no when it comes to acrylic floor finishes anyhow.

Traffic is a catalyzed waterborne isocyanate based polyurethane, which is a completely different chemistry than traditional alkyd based "polyurethanes" that have been used on hardwood floors since the 1950's. "Woodline" is Bona's conventional alkyd based polyurethane.

Welcome to Alkyd Based Polyurethanes 101:

You should be aware that conventional alkyd based polyurethanes are simply alkyd resins exactly like you find in modern oil based paints that have been "modified" by adding bi- and tri- isocyanates to the pot when cooking up the alkyd resins. An isocyanate is anything with a -N=C=O group in it, so bi- and tri- isocyanates would have two and three of those groups in them, respectively.

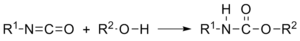

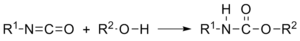

Alkyd resins are made by combining something called phthalic anhydride, glycerine and unsaturated fatty acids from plant oils (soya bean oil and corn oil mostly) and cooking them all together in a pot. The result is best described as a "clump" of long fatty acid molecules all held together with that mixture of glycerine and phthalic anhydride. Glycerine has three hydroxyl groups (-OH) on it, and those hydroxyl groups are reactive. When you add di- and tri- isocyanates to the pot when cooking alkyd resins, the isocyanates react with the -OH groups in the glycerine molecules thusly:

something-N=C=O + HO-glycerine = something-(NH)-(C=O)-O-glycerine

or:

And that ugly thing in the middle is a "urethane" linkage or urethane group.

Urethane linkages are very strong, and their effect on the alkyd resin is very much like the steel roll cage inside a race car. They make the alkyd resin much harder if you were to try to squeeze it and much stronger if you tried to stretch it. As a result, alkyd based polyurethane resins are harder and stronger than alkyd paint resins, and so alkyd based polyurethane forms a harder and stronger (more durable) film than ordinary alkyd paint, which is why alkyd based polyurethane has replaced both Carnauba Wax as the clear coating of choice over hardwood floors and varnish as the clear coat of choice over wood furniture. You need high hardness and durability to stand up well on a working surface like a floor.

(It was actually the Bayer Company (the people who make Aspirin) that patented the first alkyhd based polyurethane resins in 1956.)

Welcome to Isocyanate Based Polyurethanes 101:

Isocyanate based polyurethanes have a completely different chemistry. These are made by reacting the bi- and tri- isocyanates with chemicals that have a lot of those reactive hydroxyl (-OH) groups in them to make "blobs" of stuff that have lots and lots and lots and lots and lots of those very strong urethane linkages in them to begin with. So, those blobs are very hard and strong cuz of the large number of urethane linkages inside them. (Think of a race car with lots and lots and lots and lots of roll cages in it.) These blobs are solid, but they're so tiny that they stay suspended in water. They are not DISSOLVED in water like sugar dissolves into separate molecules in water, they're just suspended in it very much like the dirt is suspended in dirty water.

With Traffic, you get a jug that conains a slurry of those very hard and strong little blobs. Prior to spreading it on the floor, you mix in a small bottle of catalyst which causes those blobs to want to form chemical bonds between them. As the water evaporates from the Traffic, those blobs all come into close proximity and the concentration of catalyst increases (due to the evaporation of the water) and the result is that all the blobs chemically bond with one another to form a solid film on the floor.

(aside: If you could see one of those plastic blobs inside the Traffic up close, it would be clear and colourless, like clear hard ice. But, the jug of Traffic contains a milky white liquid. The reason why is because all the individual solid blobs in the jug of Traffic all reflect and refract light at each plastic/water interface. Your eye sees that jumble of scattered light rays as the colour "white". So, the Traffic was initially white for exactly the same reason that clowds and snowbanks are white even though nothing inside them is white in colour. It was the reflection and refraction of light at the gazillions of plastic/water interfaces that made the Traffic white in colour to begin with. As the blobs react with each other on the floor to form a solid film, there is less and less reflection and refraction of light because there are fewer and fewer water/plastic interfaces inside the Traffic. As the water/plastic interfaces disappear as the blobs coalesce into a solid film, the amount of reflection and refraction of light inside the Traffic is reduced to zero, and it becomes a clear and colourless solid. Generally, whenever a milky white liquid dries into a clear and colourless solid film, it's because the original liquid had all kinds of solid/liquid interfaces inside it that disappear as the liquid dries.

But, what's important is that because the film formed by the Traffic contains a much higher density of those strong urethane linkages, then Traffic forms a much stronger and more durable film than any alkyd based polyurethane ever can. So, I'm wondering why the optimum gameplan here wouldn't be to put three coats of Traffic on, rather than some of this, some of that and a little of the other.

I don't know anything about the chemistry of Bona Mega.

But, my question to your hardwood flooring contractor would be:

1. Why put the alkyd based polyurethane down first. Back in the days when you could buy linseed oil based primers and paints, Linseed Oil Based primers had great adhesion to wood because linseed oil molecules are absolutely tiny compared to alkyd resins. So the linseed oil primers would penetrate much more deeply into wood and that resulted in them having excellent adhesions to the wood. If you then top coated with an oil based paint, you'd also get chemical bonding between the linseed oil primer and the paint for excellent adhesion of the entire coating.

But, alkyd resins are much larger and don't penetrate into the wood as well. And, alkyd based polyurethane resins are much the same size as alkyd resins, so you're not going to get any better adhesion of a polyurethane to wood than you would an alkyd paint to wood. So, where is the benefit of using an alkyd based polyurethane as the first coat?

2. Why put alkyd based polyurethane down, and then Mega, and then Traffic? For the hardest and most durable film over the wood, why not put down three coats of Traffic? The Traffic will stick to the wood just as well as the alkyd based polyurethane, and with three coats of Traffic, you can expect to get at least some chemical bonding between coats.

3. Almost certainly the contractor will have to sand down the alkyd based polyurethane for the Mega to stick well to it, and then he'd have to sand down the Mega to get the Traffic to stick well to it. That's cuz all three films are a different chemistry and you wouldn't expect to get any chemical bonding between coats as you would if they were all the same chemistry. What benefit does he think he's going to get by going to all this extra work.

4. Also, it's never a good idea to put a harder film over a softer one. To confirm, just phone up your local sales rep for the S. C. Johnson Company. But, this is exactly what your contractor is proposing.

The alkyd based urethane that's going down first is also the softest of the three. The Traffic that's going on last is also the hardest of the three. And, the problem there is that things are upside down, and that means that any impact hard enough to break the weakest film will result in all three coats coming off, and your floor finish tending to "chip" when it gets hit. If he had the Traffic on first and the alkyd based poly on top, then whatever impact was hard enough to break the alkyd based poly wouldn't necessarily cause any chips because the underlying films are progressively harder and stronger and better able to withstand that impact.

(Whenever you see a surface coating that tends to have a lot of chips in it, it's normally because it's not sticking well to the substrate, or because the primer under it is softer and weaker than the top coat. The result is that any impact that breaks the weakest layer, breaks everything off.)

If it wuz me, I'd ask why not three coats of Traffic, or three coats of conventional oil based polyurethane? It seems to me that by combining them in the way he's proposing, he's creating problems by putting hard coatings over soft ones.

What you really should do is get on BonaKemi's web site and see if they have a customer service 1-800 phone number where you can talk to someone more knowledgeable about the use of their products. I simply don't see any advantage in using both Mega and Traffic on the same floor, but by the same token I don't know enough about Mega to know if there would be any benefit in doing that. It doesn sound right to me, tho, especially putting the hardest coating on top and the softest one on first. That's bass-ackwards.

Don't know if this helps.

I'm neither a hardwood flooring contractor nor a coatings chemist, but that gameplan raises a lot of questions in my mind. Right off the bat I don't see the logic in putting harder coatings over softer ones. That's a no-no when it comes to acrylic floor finishes anyhow.

Traffic is a catalyzed waterborne isocyanate based polyurethane, which is a completely different chemistry than traditional alkyd based "polyurethanes" that have been used on hardwood floors since the 1950's. "Woodline" is Bona's conventional alkyd based polyurethane.

Welcome to Alkyd Based Polyurethanes 101:

You should be aware that conventional alkyd based polyurethanes are simply alkyd resins exactly like you find in modern oil based paints that have been "modified" by adding bi- and tri- isocyanates to the pot when cooking up the alkyd resins. An isocyanate is anything with a -N=C=O group in it, so bi- and tri- isocyanates would have two and three of those groups in them, respectively.

Alkyd resins are made by combining something called phthalic anhydride, glycerine and unsaturated fatty acids from plant oils (soya bean oil and corn oil mostly) and cooking them all together in a pot. The result is best described as a "clump" of long fatty acid molecules all held together with that mixture of glycerine and phthalic anhydride. Glycerine has three hydroxyl groups (-OH) on it, and those hydroxyl groups are reactive. When you add di- and tri- isocyanates to the pot when cooking alkyd resins, the isocyanates react with the -OH groups in the glycerine molecules thusly:

something-N=C=O + HO-glycerine = something-(NH)-(C=O)-O-glycerine

or:

And that ugly thing in the middle is a "urethane" linkage or urethane group.

Urethane linkages are very strong, and their effect on the alkyd resin is very much like the steel roll cage inside a race car. They make the alkyd resin much harder if you were to try to squeeze it and much stronger if you tried to stretch it. As a result, alkyd based polyurethane resins are harder and stronger than alkyd paint resins, and so alkyd based polyurethane forms a harder and stronger (more durable) film than ordinary alkyd paint, which is why alkyd based polyurethane has replaced both Carnauba Wax as the clear coating of choice over hardwood floors and varnish as the clear coat of choice over wood furniture. You need high hardness and durability to stand up well on a working surface like a floor.

(It was actually the Bayer Company (the people who make Aspirin) that patented the first alkyhd based polyurethane resins in 1956.)

Welcome to Isocyanate Based Polyurethanes 101:

Isocyanate based polyurethanes have a completely different chemistry. These are made by reacting the bi- and tri- isocyanates with chemicals that have a lot of those reactive hydroxyl (-OH) groups in them to make "blobs" of stuff that have lots and lots and lots and lots and lots of those very strong urethane linkages in them to begin with. So, those blobs are very hard and strong cuz of the large number of urethane linkages inside them. (Think of a race car with lots and lots and lots and lots of roll cages in it.) These blobs are solid, but they're so tiny that they stay suspended in water. They are not DISSOLVED in water like sugar dissolves into separate molecules in water, they're just suspended in it very much like the dirt is suspended in dirty water.

With Traffic, you get a jug that conains a slurry of those very hard and strong little blobs. Prior to spreading it on the floor, you mix in a small bottle of catalyst which causes those blobs to want to form chemical bonds between them. As the water evaporates from the Traffic, those blobs all come into close proximity and the concentration of catalyst increases (due to the evaporation of the water) and the result is that all the blobs chemically bond with one another to form a solid film on the floor.

(aside: If you could see one of those plastic blobs inside the Traffic up close, it would be clear and colourless, like clear hard ice. But, the jug of Traffic contains a milky white liquid. The reason why is because all the individual solid blobs in the jug of Traffic all reflect and refract light at each plastic/water interface. Your eye sees that jumble of scattered light rays as the colour "white". So, the Traffic was initially white for exactly the same reason that clowds and snowbanks are white even though nothing inside them is white in colour. It was the reflection and refraction of light at the gazillions of plastic/water interfaces that made the Traffic white in colour to begin with. As the blobs react with each other on the floor to form a solid film, there is less and less reflection and refraction of light because there are fewer and fewer water/plastic interfaces inside the Traffic. As the water/plastic interfaces disappear as the blobs coalesce into a solid film, the amount of reflection and refraction of light inside the Traffic is reduced to zero, and it becomes a clear and colourless solid. Generally, whenever a milky white liquid dries into a clear and colourless solid film, it's because the original liquid had all kinds of solid/liquid interfaces inside it that disappear as the liquid dries.

But, what's important is that because the film formed by the Traffic contains a much higher density of those strong urethane linkages, then Traffic forms a much stronger and more durable film than any alkyd based polyurethane ever can. So, I'm wondering why the optimum gameplan here wouldn't be to put three coats of Traffic on, rather than some of this, some of that and a little of the other.

I don't know anything about the chemistry of Bona Mega.

But, my question to your hardwood flooring contractor would be:

1. Why put the alkyd based polyurethane down first. Back in the days when you could buy linseed oil based primers and paints, Linseed Oil Based primers had great adhesion to wood because linseed oil molecules are absolutely tiny compared to alkyd resins. So the linseed oil primers would penetrate much more deeply into wood and that resulted in them having excellent adhesions to the wood. If you then top coated with an oil based paint, you'd also get chemical bonding between the linseed oil primer and the paint for excellent adhesion of the entire coating.

But, alkyd resins are much larger and don't penetrate into the wood as well. And, alkyd based polyurethane resins are much the same size as alkyd resins, so you're not going to get any better adhesion of a polyurethane to wood than you would an alkyd paint to wood. So, where is the benefit of using an alkyd based polyurethane as the first coat?

2. Why put alkyd based polyurethane down, and then Mega, and then Traffic? For the hardest and most durable film over the wood, why not put down three coats of Traffic? The Traffic will stick to the wood just as well as the alkyd based polyurethane, and with three coats of Traffic, you can expect to get at least some chemical bonding between coats.

3. Almost certainly the contractor will have to sand down the alkyd based polyurethane for the Mega to stick well to it, and then he'd have to sand down the Mega to get the Traffic to stick well to it. That's cuz all three films are a different chemistry and you wouldn't expect to get any chemical bonding between coats as you would if they were all the same chemistry. What benefit does he think he's going to get by going to all this extra work.

4. Also, it's never a good idea to put a harder film over a softer one. To confirm, just phone up your local sales rep for the S. C. Johnson Company. But, this is exactly what your contractor is proposing.

The alkyd based urethane that's going down first is also the softest of the three. The Traffic that's going on last is also the hardest of the three. And, the problem there is that things are upside down, and that means that any impact hard enough to break the weakest film will result in all three coats coming off, and your floor finish tending to "chip" when it gets hit. If he had the Traffic on first and the alkyd based poly on top, then whatever impact was hard enough to break the alkyd based poly wouldn't necessarily cause any chips because the underlying films are progressively harder and stronger and better able to withstand that impact.

(Whenever you see a surface coating that tends to have a lot of chips in it, it's normally because it's not sticking well to the substrate, or because the primer under it is softer and weaker than the top coat. The result is that any impact that breaks the weakest layer, breaks everything off.)

If it wuz me, I'd ask why not three coats of Traffic, or three coats of conventional oil based polyurethane? It seems to me that by combining them in the way he's proposing, he's creating problems by putting hard coatings over soft ones.

What you really should do is get on BonaKemi's web site and see if they have a customer service 1-800 phone number where you can talk to someone more knowledgeable about the use of their products. I simply don't see any advantage in using both Mega and Traffic on the same floor, but by the same token I don't know enough about Mega to know if there would be any benefit in doing that. It doesn sound right to me, tho, especially putting the hardest coating on top and the softest one on first. That's bass-ackwards.

Don't know if this helps.

Last edited: