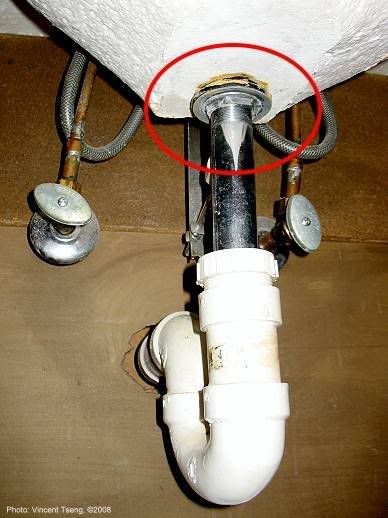

Last night my bathroom basin/sink leaked by where the drain pipe joins the bottom of the sink - when I examined the flange at the drain hole - it had corroded at the threads/joint and basically broken off -

I may be using the wrong terminology -

so here are some pics -

There is obviously a gap now at the joint -

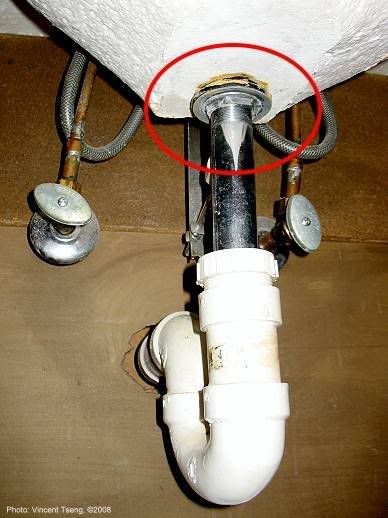

Close up -

I thought it might be simple to repair - just take the flange to a Home Depot/Lowes and ask what I need to repair this ......

But I thought I'd ask here first

- what parts should I be getting, please?

and any hints/advice in making this repair.

Also the pop-up plug is now broken at the point where the horizontal pivot rod/actuator connects

- what do I do to ensure that is adjusted correctly for the new replacement - so I don't break the new one too, and the plug seals well enough so it does not leak?

Many thanks for any advice or pointers to instructions.

I may be using the wrong terminology -

so here are some pics -

There is obviously a gap now at the joint -

Close up -

I thought it might be simple to repair - just take the flange to a Home Depot/Lowes and ask what I need to repair this ......

But I thought I'd ask here first

- what parts should I be getting, please?

and any hints/advice in making this repair.

Also the pop-up plug is now broken at the point where the horizontal pivot rod/actuator connects

- what do I do to ensure that is adjusted correctly for the new replacement - so I don't break the new one too, and the plug seals well enough so it does not leak?

Many thanks for any advice or pointers to instructions.