Initially the new panel was installed in a wall cavity where the old 60amps panels was installed (between two studs, but not screwed to any of the studs) and was simply screwed to the 1/2 plywood board, but I understand that proper support would likely require it to be screwed to studs as well. So, I decided to move the panel slightly to the left in order to screw it to the stud in the left side. Would it be against code to simply have the panel centered and screwed to the backing piece of plywood and not screwed to a stud?

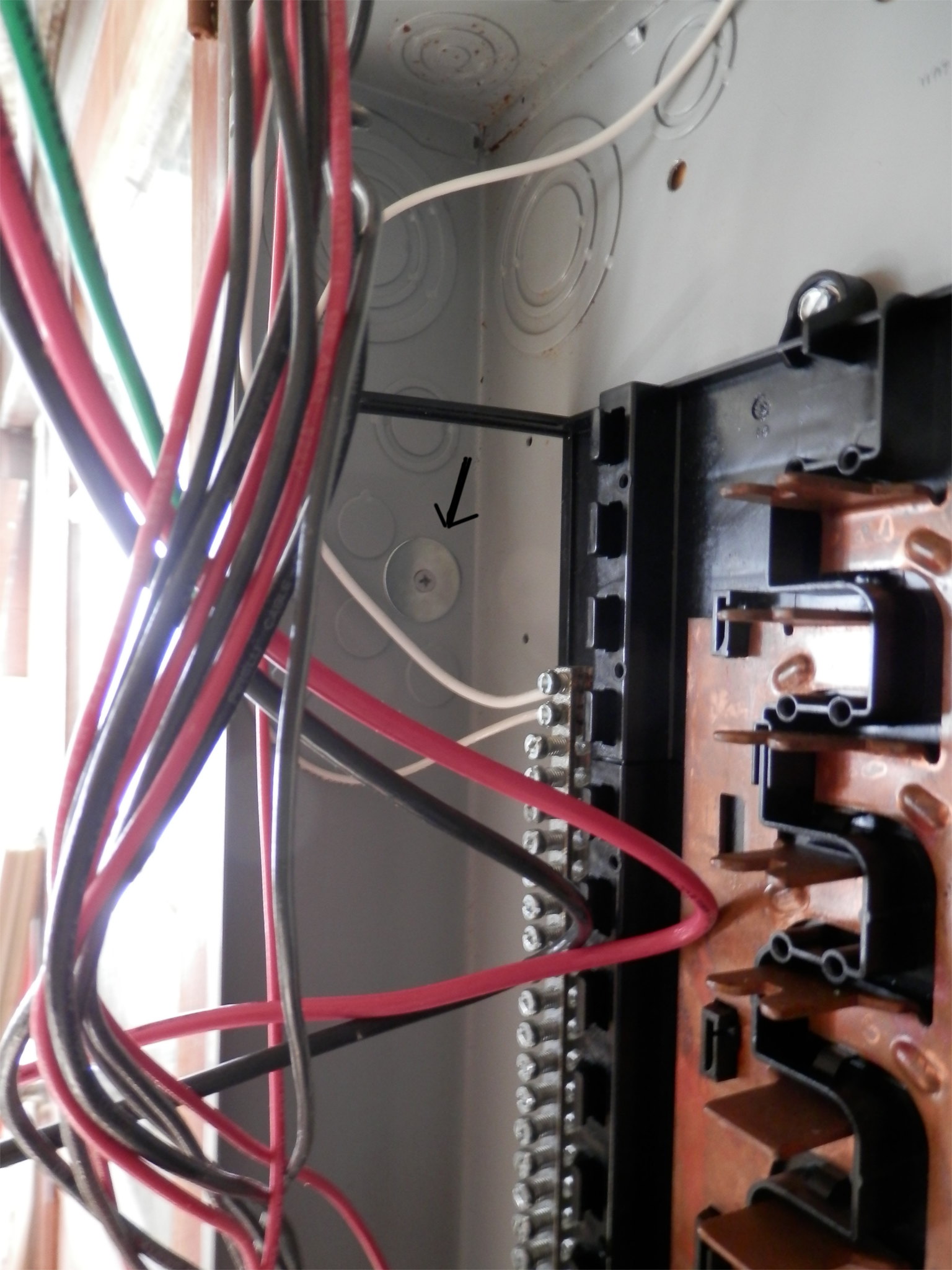

Overall the behind the new panel there is a 1/2 sheet of plywood, behind this plywood there is a 1/2 sheet of polysterene insulation and behind this insulation there the exterior sheathing (1/2 sheet of plywood) to which the exterior siding is attached. The pic below shows the panel once it was moved to the left:

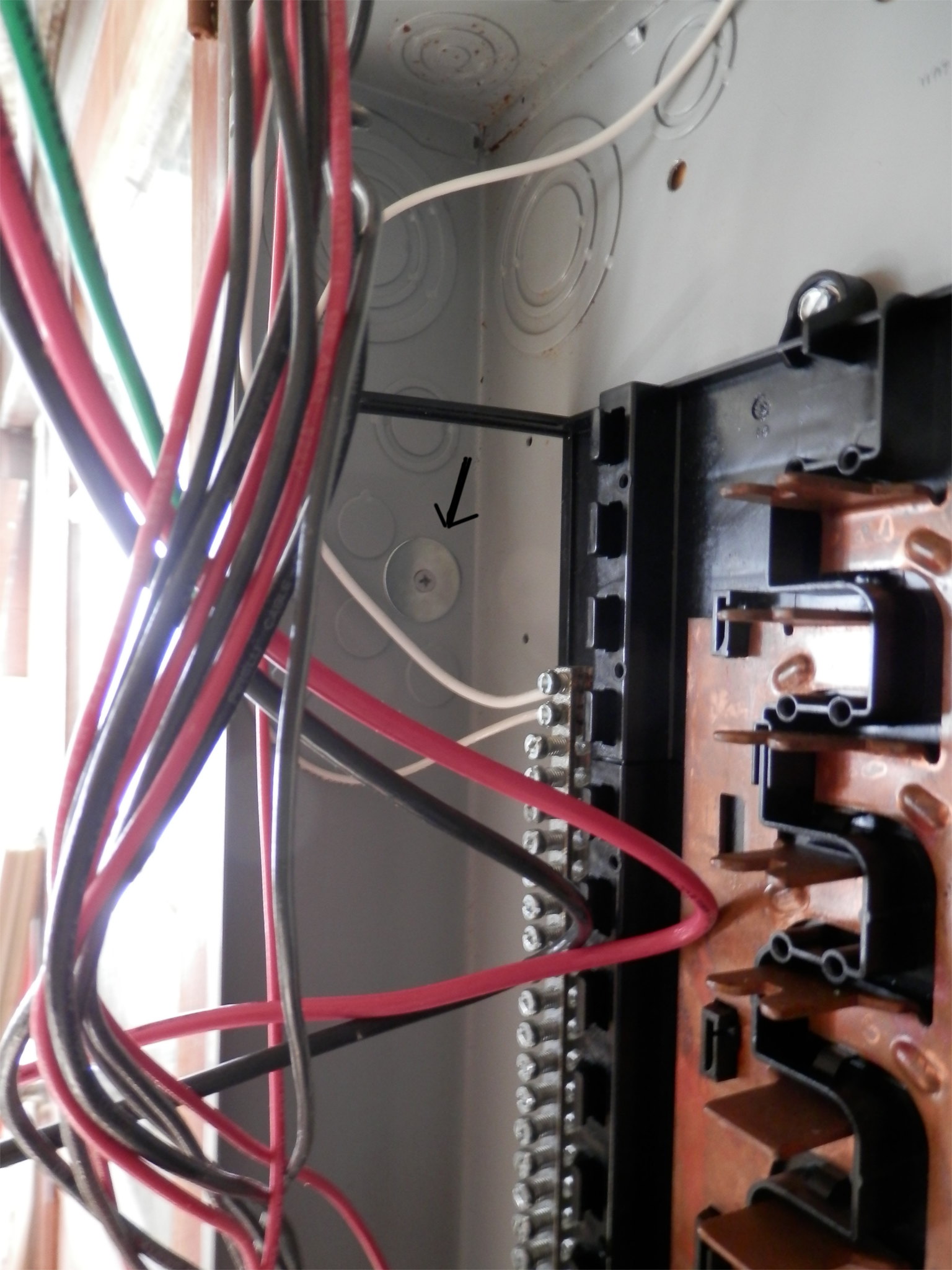

Instead of drilling holes on the panel to screw it to the stud I simply opened two knockouts on the side of the panel and used two washers to cover the knockout and provide proper support for the screw, as shown below:

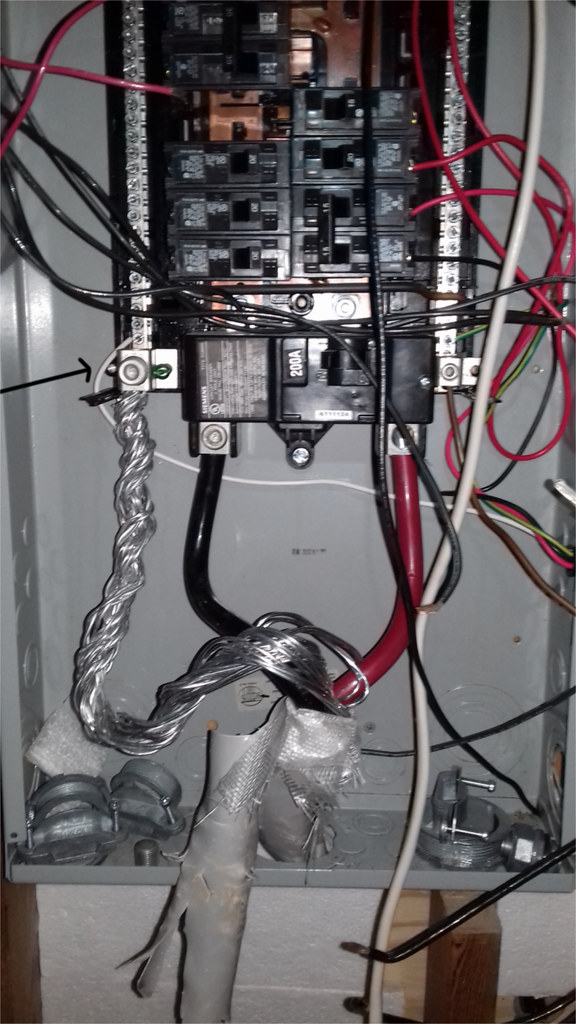

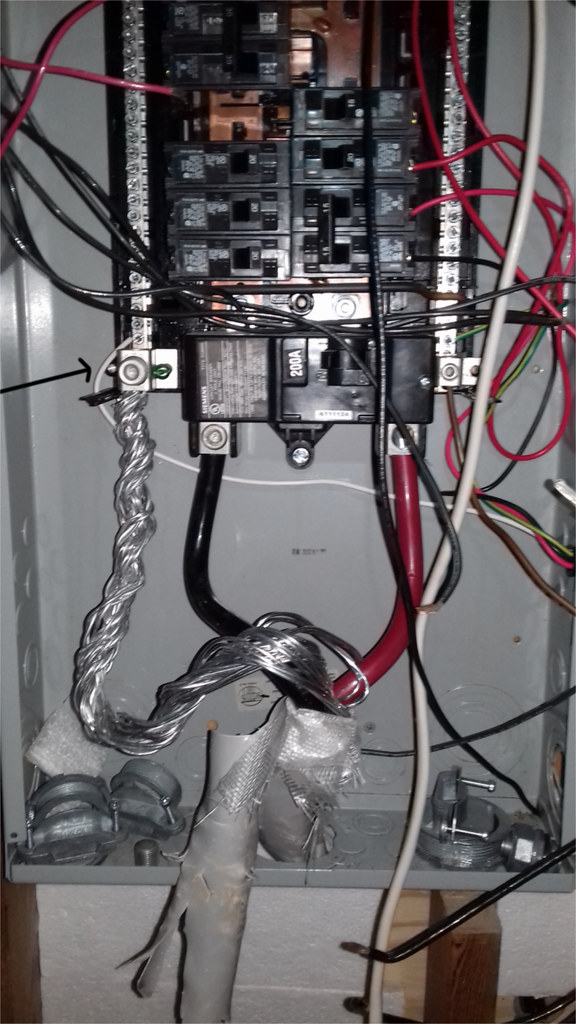

On another thing, the 200amps aluminum service entrance cable neutral filements that make up the neutral wire is giving me a hard time: I twisted it with channel locks, etc, and still can not fit it into the neutral lug in the panel as shown below:

Overall the behind the new panel there is a 1/2 sheet of plywood, behind this plywood there is a 1/2 sheet of polysterene insulation and behind this insulation there the exterior sheathing (1/2 sheet of plywood) to which the exterior siding is attached. The pic below shows the panel once it was moved to the left:

Instead of drilling holes on the panel to screw it to the stud I simply opened two knockouts on the side of the panel and used two washers to cover the knockout and provide proper support for the screw, as shown below:

On another thing, the 200amps aluminum service entrance cable neutral filements that make up the neutral wire is giving me a hard time: I twisted it with channel locks, etc, and still can not fit it into the neutral lug in the panel as shown below: