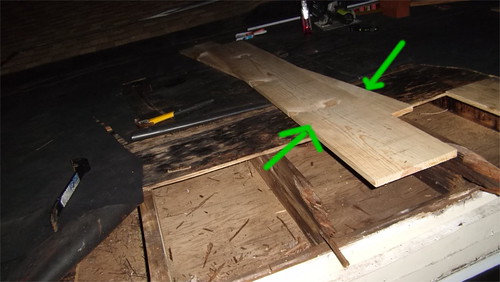

Sometime ago I posted about a all season addition to the house which has flat roof with epdm rubber membrane in a state of disrepair (ruptured epdm membrane + water infiltration + rotten plywood in some spots [specially outer edge of the ]). Few days ago I went over and when installing new fascia board (1x6) and backer support for fascia board (2 x 4) , shown below, I decided that it was about time to do a more thorough repair:

(shows new fascia primed/sealed in white, 2x4 support for fascia, and weak + rotten portion of plywood 1/2 removed)

It seems that they used super cheap nails which one could simply pull out due to corrosion. I am using 3" high quality exterior screws throughout.

But the main issue I was faced with was to perform a perfectly straight cut with the circular saw on top of the roof in order to remove that bad roof sheathing. As a result, I got to much of a gap; and sometimes a not perfect even gap:

In some spots I may have 1/4" of a gap between the sheathing or even 1/2" which seems to much. Is there anything that can be done to mitigate this larger gap (caulking with some flexible sealant that would not compromise expansion and contraction of the wood?)?

Thanks

(shows new fascia primed/sealed in white, 2x4 support for fascia, and weak + rotten portion of plywood 1/2 removed)

It seems that they used super cheap nails which one could simply pull out due to corrosion. I am using 3" high quality exterior screws throughout.

But the main issue I was faced with was to perform a perfectly straight cut with the circular saw on top of the roof in order to remove that bad roof sheathing. As a result, I got to much of a gap; and sometimes a not perfect even gap:

In some spots I may have 1/4" of a gap between the sheathing or even 1/2" which seems to much. Is there anything that can be done to mitigate this larger gap (caulking with some flexible sealant that would not compromise expansion and contraction of the wood?)?

Thanks