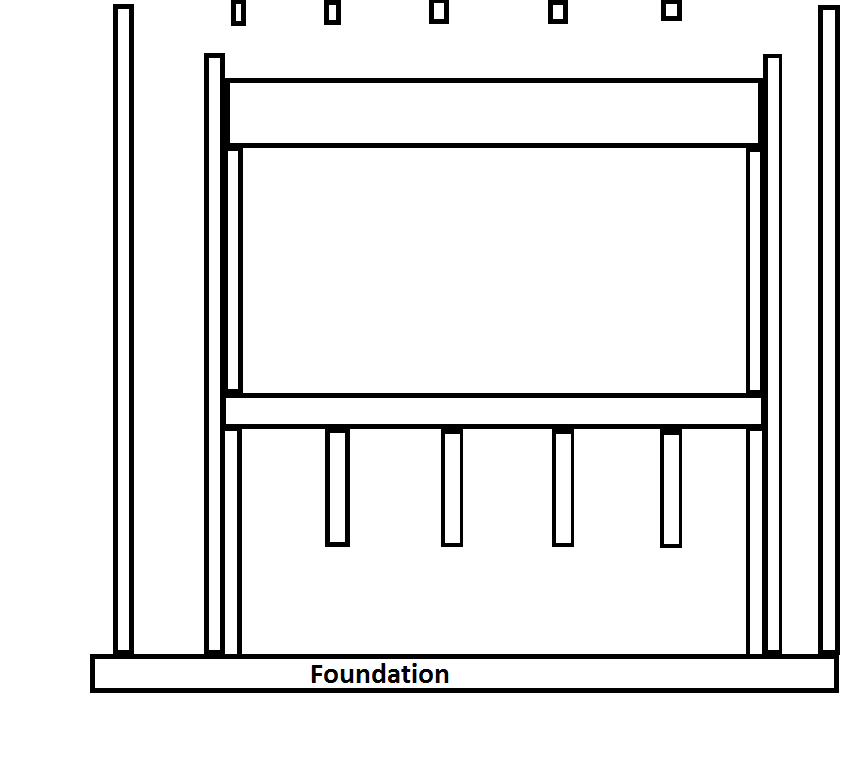

Guys, here's an updated picture:

http://tinyurl.com/qam969o

I'm going to refer to a few things, so I noted some numbers on the picture:

http://tinyurl.com/py9gajq

First - almost nothing in the pictures is nailed - so I can still play with it.

Also, I'm planning on adding one sill under the header and one over the 4x4.

1:

I put a 4x4 beam to serve as support for the future large window.

The studs in the middle are not studs - they are half loose and cut right below the floor level.

The beam rests on actual studs on each end. So this is definitely not a classic window framing. Any issues with this that you can see?

2: Behind the number 2 there are 3 pieces of wood.

The rightmost is the window stud, from the beam to the header.

The middle is a stud that I added, and nailed at the bottom to the existing stud.

The leftmost is not a stud, but a 2x4 that is nailed to the external board.

I plan to remove the leftmost piece. But the issue is that the new stud is not level. The stud below is also not level. And the stud to the left of all this, is also not level.

The degree of unlevel is not very high. But I was thinking about adding 2x4 pieces perpendicular to and between the new stud and the existing stud to the left. What do you think?

3: The header right now is longer than the 4x4 beam. That is because of the unlevelness of the studs. How big of a concern is this?

4: I was thinking of adding a long 2x4 spanning from leftmost stud of the wall to the 2nd rightmost stud of the wall, and then nailing the studs to it. Thoughts?