You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mounting Ceiling Fan

- Thread starter demoso

- Start date

Help Support House Repair Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jeffmattero76

Well-Known Member

- Joined

- Jan 4, 2016

- Messages

- 235

- Reaction score

- 89

I can't really tell from the pictures. Unless that box is screwed into a joist, or suspended from a bar that is screwed into two joists, the answer is no.

If you remove that ceiling box, you can get a fan rated bar with a box that you can use without doing and demo work to the ceiling. The orange big box sells them.

https://www.homedepot.com/p/Westing...fit-Ceiling-Fan-Saf-T-Brace-0110000/204845572

If you remove that ceiling box, you can get a fan rated bar with a box that you can use without doing and demo work to the ceiling. The orange big box sells them.

https://www.homedepot.com/p/Westing...fit-Ceiling-Fan-Saf-T-Brace-0110000/204845572

Brian Famous

Well-Known Member

I agree with Jeff, it's a matter of what is supporting that box.

Climbed up in the attic and pulled the insulation back. It is a metal bar holding the box attached to the joists on each end. I can’t see if it’s screws or nails cause it’s connected in the under side of the joist against the drywall but it’s definitely in there good. I pushed hard with my hand and it didn’t budge. Here’s some pics. What ya think?I can't really tell from the pictures. Unless that box is screwed into a joist, or suspended from a bar that is screwed into two joists, the answer is no.

If you remove that ceiling box, you can get a fan rated bar with a box that you can use without doing and demo work to the ceiling. The orange big box sells them.

https://www.homedepot.com/p/Westing...fit-Ceiling-Fan-Saf-T-Brace-0110000/204845572

I agree with Jeff, it's a matter of what is supporting that box.

Climbed up in the attic and pulled the insulation back. It is a metal bar holding the box attached to the joists on each end. I can’t see if it’s screws or nails cause it’s connected in the under side of the joist against the drywall but it’s definitely in there good. I pushed hard with my hand and it didn’t budge. Here’s some pics. What ya think?

Attachments

mabloodhound

Restoration & Renovations

- Joined

- Jun 21, 2008

- Messages

- 416

- Reaction score

- 183

Those are NOT "bent over tabs". They are punched through the box and formed.That is not a fan rated box. A fan rated box will mounting points stronger than those bent over tabs on the box you have.

Irregardless of how the box was made it is not suitable for fan support. The boxes which are suitable for that application have threaded sockets welded in place, screws which were run through holes in the box and held in place with toothed washer lock nuts, or other effective means of transferring the weight of the fan to the support bar. You have several options.

One is removing the cable and cutting the support bar from above with a right angle grinder of other cut off tool and then installing a new ceiling fan hanger bar with fan box.

Another is installing 2 hanger bars on either side of the box to support #10-24 or larger screws held in place with a lock nut. The latter allows you to support the fan from 2 substantial hanger bars that each have mounting flanges that you screw into the side of the joist with #10 or larger wood screws that are 1&1/2 inches long. The hanger strap or plate that is shipped with the ceiling fan can then be supported from the 10-24 machine screws that point down from the hanger bars using lock nuts and washers as needed.

That cable appears to be "Rag Wire" which is the cloth jacketed cable that was the first material used to jacket Non Metallic Cable (NMC). I could not see an Equipment Ground Conductor (EGC) in that cable. If there isn't one you will need to take additional steps to render the installation safe.

Tom Horne

One is removing the cable and cutting the support bar from above with a right angle grinder of other cut off tool and then installing a new ceiling fan hanger bar with fan box.

Another is installing 2 hanger bars on either side of the box to support #10-24 or larger screws held in place with a lock nut. The latter allows you to support the fan from 2 substantial hanger bars that each have mounting flanges that you screw into the side of the joist with #10 or larger wood screws that are 1&1/2 inches long. The hanger strap or plate that is shipped with the ceiling fan can then be supported from the 10-24 machine screws that point down from the hanger bars using lock nuts and washers as needed.

That cable appears to be "Rag Wire" which is the cloth jacketed cable that was the first material used to jacket Non Metallic Cable (NMC). I could not see an Equipment Ground Conductor (EGC) in that cable. If there isn't one you will need to take additional steps to render the installation safe.

Tom Horne

If you take the angle grinder up in the crawl space take along a fire extinguisher also just in case.

If it were mine I would cut 2 (2x4) to fit snugly between the joists and pre-drill some angled holes thru the end for deck screws to (toenail) toe screw them to the joists one on each side of the hanger strap. Then I would go back down stairs and drill a couple holes thru the existing box and run a couple deck screws up into the new 2x4.

If you are careful there should be no damage or patching needed below and that box should now be strong enough to hold a normal ceiling fan.

If it were mine I would cut 2 (2x4) to fit snugly between the joists and pre-drill some angled holes thru the end for deck screws to (toenail) toe screw them to the joists one on each side of the hanger strap. Then I would go back down stairs and drill a couple holes thru the existing box and run a couple deck screws up into the new 2x4.

If you are careful there should be no damage or patching needed below and that box should now be strong enough to hold a normal ceiling fan.

mabloodhound

Restoration & Renovations

- Joined

- Jun 21, 2008

- Messages

- 416

- Reaction score

- 183

I agree with Bud, that a 2x inserted between the joists would be the easiest fix and plenty strong.

Eddie_T

Well-Known Member

- Joined

- Feb 16, 2015

- Messages

- 3,386

- Reaction score

- 3,296

Of course I would have to be there to know for sure but what you have in place looks good to me. I would probably install the fan and crawl back in after a few weeks of operation for inspection. Another thought would be a single 2x2 or closet pole directly on top of the bar and a couple of hose clamps to the bar.

An angle grinder, unlike say a welder, is not generally considered "Hot Work"; that is work that is likely to kindle a fire. An abundance of caution will do you no harm though.If you take the angle grinder up in the crawl space take along a fire extinguisher also just in case.

If it were mine I would cut 2 (2x4) to fit snugly between the joists and pre-drill some angled holes thru the end for deck screws to (toenail) toe screw them to the joists one on each side of the hanger strap. Then I would go back down stairs and drill a couple holes thru the existing box and run a couple deck screws up into the new 2x4.

If you are careful there should be no damage or patching needed below and that box should now be strong enough to hold a normal ceiling fan.

For reasons that I won't bore you to tears with, it would be good if that extinguisher were water based. Since it is unlikely that you own a water extinguisher you could bring a garden sprayer of water, with a small amount of dish detergent mixed in, along with the fire extinguisher.

If you are feeling nervous about this then have a garden hose that is long enough to reach the attic laid out by the outside door that gives the shortest route to the attic and turned on up to the nozzle. If you could not run that hose to the attic really quickly; such as when it is not the level right above the outside door where the hose would be laid out; then you may want to use a new hose washer and a new nozzle or in line shut off as needed to prevent any leaking at the nozzle end and lay the hose into the attic before you need it.

I really wouldn't bother with the hose at all unless the home were in an area that is not served by a close by fire station or one without fire hydrants. You'll have to forgive me. I'm a retired Firefighter with 35 years of active service so I just think in worse case terms.

Again let me point out that the sparks from an angle grinder are not generally hot enough to ignite ordinary combustibles.

--

Tom Horne

Wesley Charles

New Member

Eek - I would want some more support!

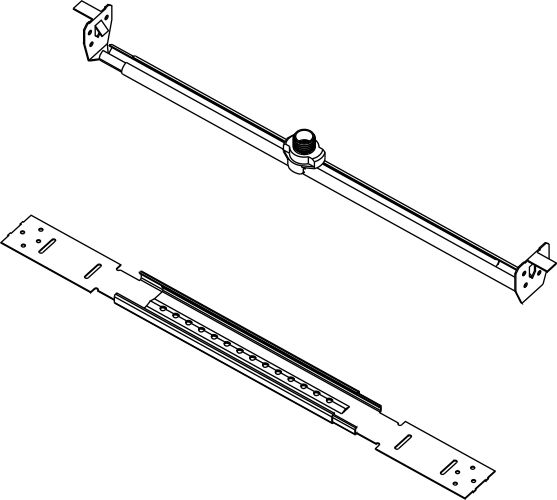

The reason that I suggested using heavy hanger bars, like the lower one in this image,I agree with Bud, that a 2x inserted between the joists would be the easiest fix and plenty strong.

is because they are adjustable in length and easier to get a tight fit on between the joists. Also because the right angle brackets at each end make them easier to install.

If your not experienced with "Toe Nailing" nails into wood blocks it can be hard to avoid damaging the plaster from above. If you do hang wood blocks drive the nails from the side so that any shifting will be sideways rather than down through the sheet rock. Pre drilling the blocks for screws and using screwed in place stud hangers

work really well also.

--

Tom Horne

The garden sprayer is likely to hold a couple of gallons of water. A spray bottle may hold only a pint. The reason I suggested water with a little dish soap is that if something were to start smoldering the water would penetrate to the seat of the combustion and put it dead out. A dry chemical fire extinguisher will suppress the open burning but will not complete extinguishment immediately. There have been a number of well documented incidents were a fire that was knocked down with dry chemical came back to life when it wasn't properly overhauled.Or you could put a little water spray bottle.

--

Tom Horne

I agree @hornetd Tom that it would be pretty hard to start a fire with an angle grinder. I use mine all the time in my workshop and never caught anything ablaze. But 43 years in a large industrial setting has told me if this was at work we would have to comply with a hot work permit and also all the confined work space rules. I have seen guys spray sparks into a cup of gasoline showing how safe grinding is. But I also know they will give a good hot foot when they get in your boot. I have also seen them melt into plastic and pit glass.

For me places I worry about most are attics and barns. They have their share of dry dust bunnies and dust.

As to nails and screws. Over the last 10 years I haven’t used a half pound of nails in all my home remodeling efforts. With the positive drive deck screws they have now a days and being able to get them out as easy as putting them in without any impact on the surrounding area its screws all the way. I have tore a lot of things apart in my life and and screws are just miserable to get to let go. I mostly use nails now to hang tools on. Drilling a pilot hole is a little more work but in a delicate situation like the OP it is what I would do. The hangers are a good idea also as are the adjustable brackets. I just normally don’t have that stuff handy and the time to go buy it and the cost of gas and supplies I would have it done with some scraps I never throw away of framing wood.

As they say in Texas there is a lot of ways to skin an armadillo.

For me places I worry about most are attics and barns. They have their share of dry dust bunnies and dust.

As to nails and screws. Over the last 10 years I haven’t used a half pound of nails in all my home remodeling efforts. With the positive drive deck screws they have now a days and being able to get them out as easy as putting them in without any impact on the surrounding area its screws all the way. I have tore a lot of things apart in my life and and screws are just miserable to get to let go. I mostly use nails now to hang tools on. Drilling a pilot hole is a little more work but in a delicate situation like the OP it is what I would do. The hangers are a good idea also as are the adjustable brackets. I just normally don’t have that stuff handy and the time to go buy it and the cost of gas and supplies I would have it done with some scraps I never throw away of framing wood.

As they say in Texas there is a lot of ways to skin an armadillo.

Michael Armstrong

Well-Known Member

There are also hanger bars that can be inserted through the existing hole, spread to press against a pair of joists, and tightened in place, such as this:

it's $16: https://www.amazon.com/Westinghouse-Lighting-0110000-Saf-T-Brace-Ceiling/dp/B00027EWNW, supports light fixtures up to 150 pounds on 16-inch centers; fixtures up to 50 pounds on 24-inch centers; fans up to 70 pounds.

it's $16: https://www.amazon.com/Westinghouse-Lighting-0110000-Saf-T-Brace-Ceiling/dp/B00027EWNW, supports light fixtures up to 150 pounds on 16-inch centers; fixtures up to 50 pounds on 24-inch centers; fans up to 70 pounds.

For what it may be worth if I were dealing with your situation I would be able to modify the box to support any ceiling fan weighing less than 25 pounds. In no case would I support the fan from the original box ears. There are too few threads of screw engaged in the box to reliably support a vibrating motor. The biggest unknown here is how the box bar is supported. That was almost invariably done with nails. Shorter nails were higher count when purchased by the pound so the nails used were likely to be 1&1/2 inches or less in length. Shorter nails take less time to drive and were more frequently used especially in tract housing. This is the biggest unknown in this installation. Whom ever's suggestions you decide to use, the most important point is do not depend on that existing box bar to support a fan of any size!

[Rant Mode]All subcontractors get pushed hard to reduce costs by market pressure. From this pressure comes the subcontractor Rant that "A good description of a General Contractor is a fella who would cut his own mother's throat for five cents off on a 100 board foot of lumber." [/Rant Mode]

--

Tom Horne

[Rant Mode]All subcontractors get pushed hard to reduce costs by market pressure. From this pressure comes the subcontractor Rant that "A good description of a General Contractor is a fella who would cut his own mother's throat for five cents off on a 100 board foot of lumber." [/Rant Mode]

--

Tom Horne

Eddie_T

Well-Known Member

- Joined

- Feb 16, 2015

- Messages

- 3,386

- Reaction score

- 3,296

I like that Westinghouse brace. There was nothing like that available (at least in my area) when I installed my fans. My fans (three) are on regular octagon boxes with longer screws. Fortunately they have survived some 25 years or more, maybe only because I have quality fans with little to no vibration (but I have seen fans that rock back and forth).

In retrospect I should have put lock nuts on those screws (that might be an option for the OP). He might also locate the attachment tabs for the bar, add long screws into the joist then fill holes in sheet rock with a bit of spackle.

In retrospect I should have put lock nuts on those screws (that might be an option for the OP). He might also locate the attachment tabs for the bar, add long screws into the joist then fill holes in sheet rock with a bit of spackle.

Last edited: